Contract for TESS in Arctic Offshore Farming Project

TESS is using known technology in new applications for deliveries to a new record-breaking project that involves building a submersible fish farm at sea.

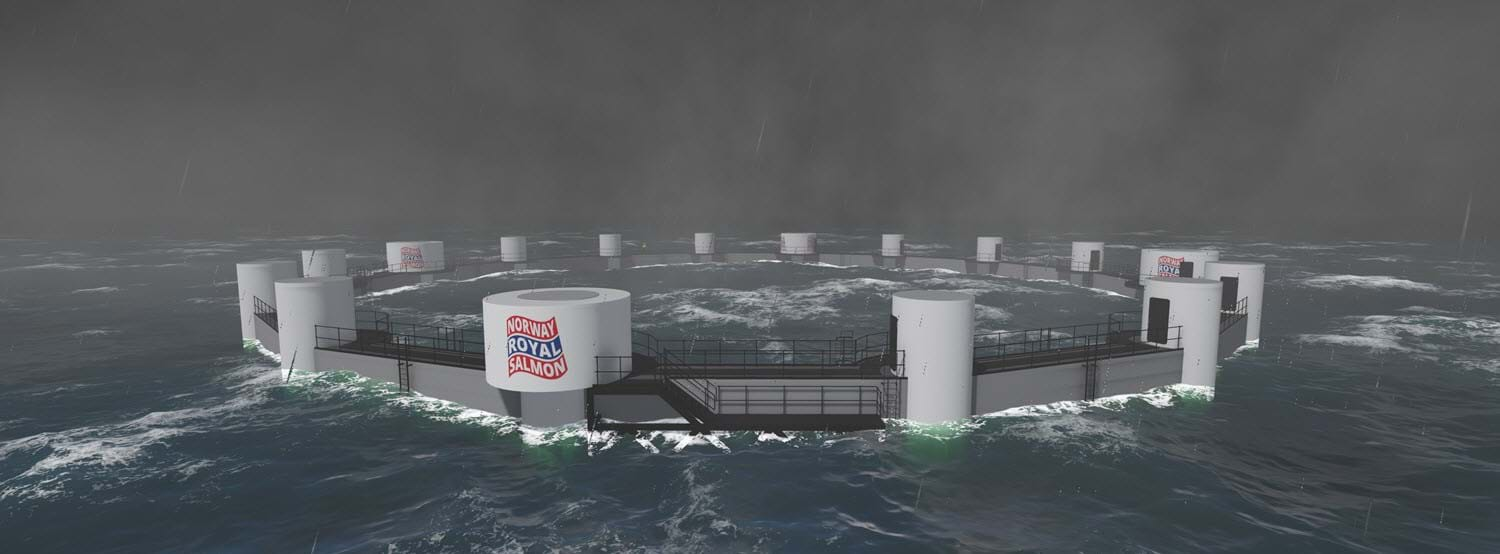

Norway Royal Salmon (NRS) has developed a submersible fish farm at sea, which is dimensioned for weather-hardy areas and gives the salmon the opportunity to be in the open sea.

TESS has developed the system and supplies cage hoses, pipes, cables, buoyancy elements and accessories for the record-breaking project.

The Backdrop

The project originated in the autumn of 2015, when Norway Royal Salmon established a collaboration with designers and engineers in Aker Solutions.

Over 60 different concepts were developed over the next few months, based on functional requirements from NRS.

In March 2016, the current solution was chosen and development permits were sent to the Directorate of Fisheries.

Exactly two years later, NRS received a commitment from the Norwegian Directorate of Fisheries for eight development permits. The Directorate requires that the project be documented methodically, so that the knowledge can be shared and available to the industry.

NRS sent out information to 90 potential suppliers and held meetings with 30 of these in a short time, including TESS. The project responsibility has been anchored with Innovation Director Jan Dyre-Hansen and Division Manager for Hoses, Lars-Otto Fredriksen since the autumn of 2018.

Together they have been responsible for the commercial and technical responsibility in the project.

- We held our first meeting with NRS and Aker Solutions in September 2018, says Lars-Otto Fredriksen in TESS.

Before the summer of 2019, TESS will deliver an engineering report with suggestions and recommendations for solutions. After the summer, the meeting activity begins to pick up speed, and until the end of October the same year, TESS, NRS and Aker had weekly meetings, where the details of the contract were reviewed and secured.

On 11 November 2019, TESS signed the agreement with NRS for the delivery of cage hoses, pipes, cables and accessories for the project - the largest single agreement in TESS ever. The same month, it was decided to place Arctic Offshore Farming on Fellesholmen outside Kvaløya in Troms.

Submersible Fish Farm. Photo by Norway Royal Salmon.

Critical Components and Crossover Technology

The cage hoses that are delivered and installed consist of technically integrated hoses, pipes and cables that are to transport feed, air, electricity and fiber-optic signals from the feed raft to the cages.

In addition, a robust hose will transport dead fish and leftovers from feed back to the feed raft.

Photo: The assembly team connects the fastening joints to the hoses. Photo:©TESS

The fish farm is submersible and designed to stand in the open sea, this means that salmon lice are largely avoided, among other things. The industrial project will contribute to sustainable growth for the Norwegian aquaculture industry and contribute to the FAO's (UN) ambitious goal of growth in the aquaculture industry globally.

The facility consists of two individually anchored cages with a diameter of 77 meters and room for 3,000 tonnes of fish in each, as well as a feed raft. The cages and the feed raft are in a triangular shape at a distance of 230 meters from each other.

The cage hoses are 300 meters and are arched 20 meters below sea level. In addition, a triple cable of 450 meters is located between the cages. All hose and cable solutions are immersed with anchorage in the seabed and have floats that allow the desired depth to be maintained. This innovation technology requires accurate calculations, quality products, and perhaps most importantly - relevant experience.

- What is our innovation is to use known technology in new applications. The cage hoses are critical components in the system and there are many important factors that determine if they will work. TESS's long experience within the oil and gas and aquaculture industry, means that we can confidently choose solutions that have been tested and are suitable for this demanding environment, says Fredriksen.

Assembly Team On Site

The assembly team consisted of Tommy Thorvaldsen, Rune Søhus, Christoffer Soot, Geir Magne Nesset, Christian Ørpen Thorstensen, Trond Sørensen, Geir Solberg and Magnus Jølberg.

The first team travelled to Fellesholmen on 18 May. All hoses, cables and tools had been sent up in advance, and the plan had been thoroughly reviewed. 2-week intervals of six weeks with 12-hour working days lay ahead of the team, including Saturdays.

The teams where never spoiled with hot summer days, but also not tested by the wild forces of nature that the north can offer. Nevertheless, the weather conditions fluctuated so that the clothing varied between one layer and three layers of clothing up to several times a day.

Delivers on Time

Currently, TESS is keeping track of the delivery and delivering its systems according to the agreement. The pandemic situation in the world has presented some challenges, but frequent dialogue with all parties has kept them on track.

– It has been almost painless. The assembly team has been persistent and in addition been very lucky with the weather, so we are according to schedule, says Fredriksen

If you would like to learn more about this delivery, you can contact:

Lars-Otto Fredriksen

Division Manager for Hoses

TESS Vest

Phone: +47 32 84 40 21

or

Jan Dyre Hansen

Innovation Director

TESS Vest

Phone: +47 32 84 40 04

TESS is a Norwegian and nationwide supplier of products and services to the MRO market.

Their core products are hoses and hose fittings for all purposes with corresponding services.

TESS is a member of GCE Ocean Technology since 2008.